Automatic Flute Laminating Machine

Used for corrugated board lamination

The fully automatic flute laminating machine supplied by HUAYU is mainly used to laminate linerboards to the flutes of corrugated board or laminate one cardboard to another cardboard with adhesive. The suitable corrugated flute patterns include A, B, C, E and F flute. This automatic flute laminator is designed with auto suction feeding system for both top linerboards and bottom corrugated boards. It is really an ideal choice for producing high end packaging boxes.

| Model | |

|

||

| Max. sheet size (mm) | 1300×1100 | 1450×1100 | 1600×1400 | |

| Min. sheet size (mm) | 350×350 | 350×350 | 350×350 | |

| Bottom paper | Min. weight (g/m2) | 300 | 300 | 300 |

| Max. weight (g/m2) | 800 | 800 | 800 | |

| Max. thickness (mm) | 10 | 10 | 10 | |

| Top paper | Min. weight (g/m2) | 150 | 150 | 150 |

| Max. weight (g/m2) | 800 | 800 | 800 | |

| Margin of error of fitting (mm) | ±1.0 | ±1.0 | ±1.0 | |

| Max. machine speed (pcs /min) | 100 | 100 | 100 | |

| Total power (kW) | 12 | 12 | 12 | |

| Machine length (m) | 10.00 | 10.00 | 10.00 | |

| Total weight (kg) | 5500 | 6000 | 6000 | |

- The flute laminator has a unique pressing spring front lay registration design, reducing mechanical failure rates and ensuring accurate lamination positioning with intelligent PLC control.

- Equipped with a frequency converter for speed adjustment and PLC for centralized control, ensuring synchronization with the production line.

- Double servo motors control bottom paper feeding, achieving timely and accurate alignment with the front lay, ensuring precision even during operational adjustments.

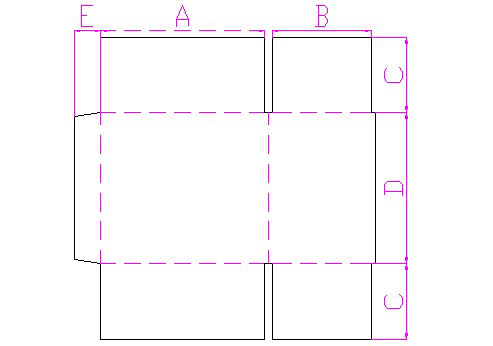

- The flute laminating machine features an enhanced gluing uniformity thanks to its gluing roller with a high-middle design, complemented by a patterned (engraved) spreading roller. This design improves the uniformity of glue application on the cardboard, enhancing the overall lamination strength and reducing production costs.

- Balanced and stable operation: Steel rollers undergo balancing and testing, combined with tight assembly techniques, which enhance machine stability The main transmission uses timing belts, directly absorbing paper at the bottom for improved accuracy and speed.

- Features a surface control system with automatic and recyclable glue circulation, significantly reducing labor intensity.

- The feeder developed by HUAYU, is paired with a pre-stacking device, reducing downtime and improving efficiency.

- All materials used to manufacture the flute laminating machine are inspected according to ISO-9001 standards, with key parts like bearings from well-known brands, ensuring durability.

- This flute laminator is suitable for 150-450GSM face paper and A, B, C, D, E, F flute corrugated sheets, as well as three and five-ply cardboard, up to a maximum thickness of 8mm.