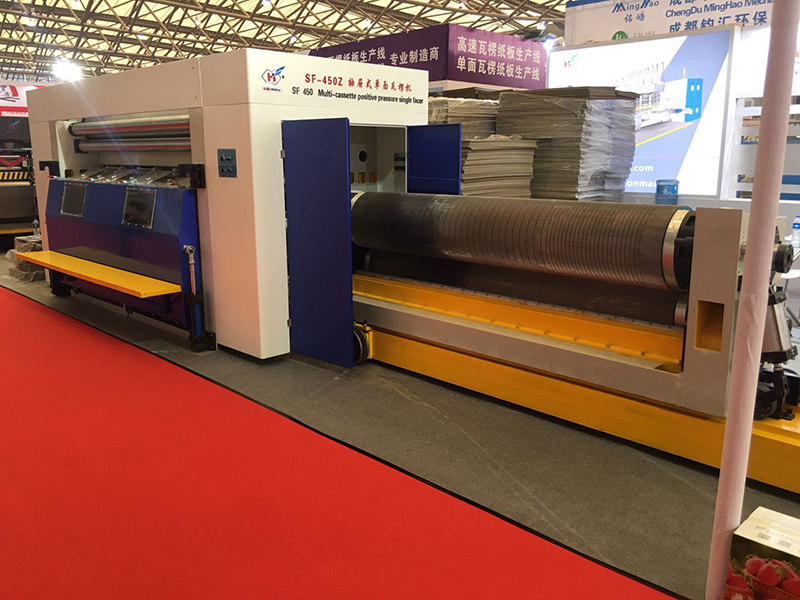

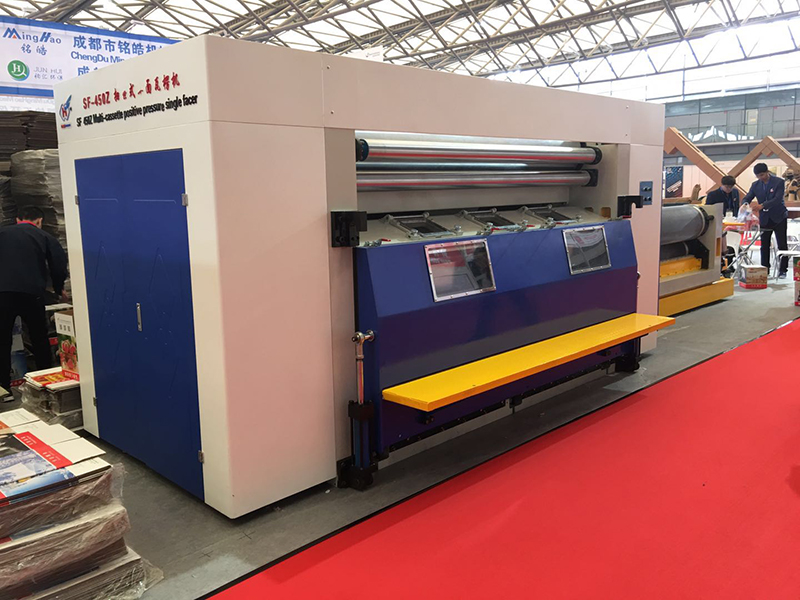

SF-450Z/550Z

Cassette Single Facer

Corrugating machine

Features

- Design speed: The SF-450Z has a working speed of 250m/min and the SF-550Z of 300m/min.

- Effective width: Ranges from 1400mm to 2500mm.

- Corrugated roller diameter: Available in ⌀450mm and ⌀550mm.

- Positive pressure design: Ensures low heat loss, evenly compresses the core paper onto the corrugated roller for optimal corrugation, and uniformly applies glue for better adhesion of single-sided corrugated paper.

- Quick roller change: Rollers can be changed in just 10 minutes, with an electric trolley for towing and a hydraulic motor to drive the corrugated rolls into the cassette single facer. Hydraulic systems lock the rollers in place, allowing for easy and swift replacements.

- Quality roller material: Both main and auxiliary rollers are made of high-quality alloy steel, heat-treated, and surface-sprayed with tungsten carbide post-grinding.

- Hydraulic control system: Offers high stability for corrugating and pressure rollers, supplemented by pneumatic control for buffering and electric control for gap adjustment.

- Glue application control: Electrically adjusted glue application with an independent operating system to prevent drying when the single facer stops.

- Moveable gluing system: Designed for ease of cleaning, maintenance, and repair.

- User-friendly operation: Features a simple control system with a touch screen interface, displaying operational status, functions, fault indicators, and allowing parameter adjustments.

- Built-in spray system: Adjusts the temperature and moisture of the core paper.

- Durable bearings: The bearings in both the main and auxiliary corrugated and pressure rollers use high-temperature grease for extended life and smooth operation.